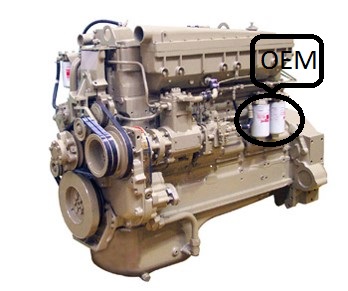

CURRENT STANDARD FITTED OIL FILTRATION SYSTEMS

OEM SUPPLIED FILTERATION

- Designed to remove relatively large dirt particles which are less in number 10um

- Subject to vibration which will dislodge any particles smaller than the pore size of the filter paper

- Will not remove sludge because of large pore hole diameter

- Will only withstand a differential pressure of less than 50 kPa before breaching occurs

- Have a built in relief valve that opens when this differential pressure goes above 50 kPa

- Have become a consumable item of worth to the manufacturers

SLUDGE

One oil company described sludge as engine cholesterol and this is a very good description of how it works. It can form hard pockets of a very sticky substance which through centrifugal force in the crank shaft can block oil channels etc. thus impeding the flow of oil to the bearings.

What about the engine oil?

Engine oil doesn't wear out, but becomes contaminated because of external factors and ineffective filtration

UDF OIL FILTRATION SYSTEMS

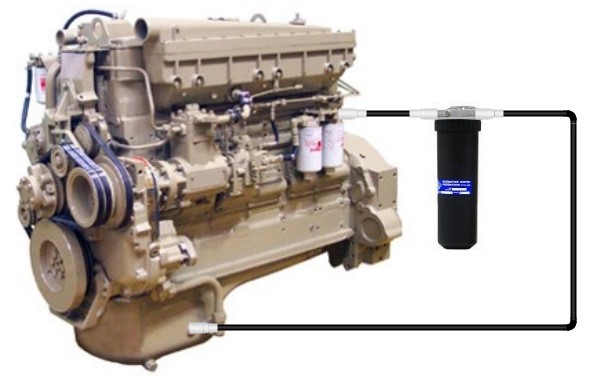

ENGINE OIL BY-PASS SYSTEM

Oil By-Pass Filtration is not a new idea or new technology,

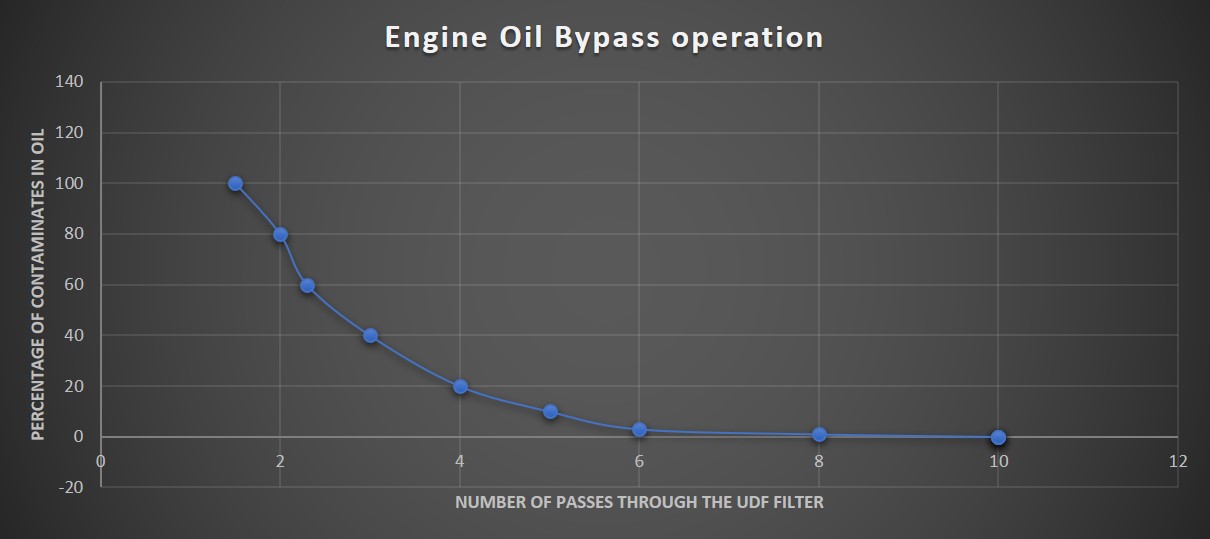

It’s just a great option that has been forgotten. Maintain engine oil within the engine manufacturers specification by continuously removing contaminants that are entering or being created in the engine. By eliminating the “Chain Reaction of Wear” – engine and component life is greatly extended. Sludge is continuously removed ensuring that the internal parts are kept clean. Additive package is not overloaded by contamination and is thus more effective over the service interval. A small amount of oil (± 5%) is taken from the engine circulated through the By-Pass filter.Up to 95% of all particles above 1 micron are removed and the oil is returned back to the sump. After a short period of time the oil will be up to 20 times cleaner than with standard filtration.

How Does Bypass Filtration

- Oil circulates approximately 20Ltr per min on small to medium size engine and 80Ltr per min on large equipment.

- A very small percentage (5%) is tapped off and fed through the UDF Bypass system.

- 95% of all particles above 1 micron are removed and return back to the sump.

- Over a period of 20min the total oil capacity is filtered through the system.

- Within 1 hour the has cycle through the UDF system 3 times

- the Oil is maintained at 20 times cleaner.

The UDF by-pass filter system will remove 95% all contaminant within a short time allowing faster flow of oil through the engine and aiding cooler operation of both engine bearings and extend the life of the oil to 1500 hrs

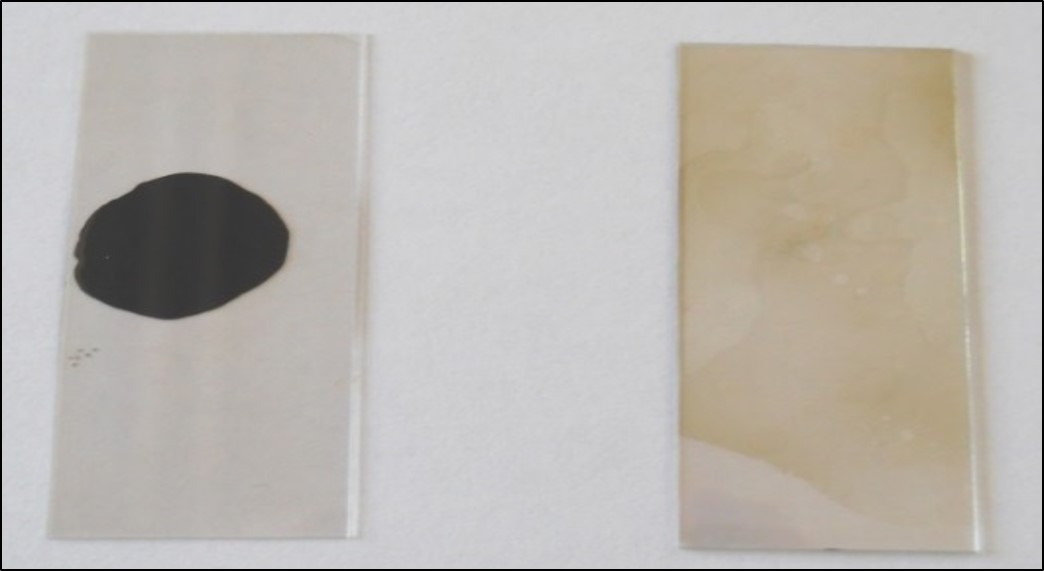

A quick test to check Contamination

Place a drop oil from the dip stick, squeezed between 2 thin sheets of glass will show if the oil dispersal package is still effective and fit for further use or overloaded with soot.

OIL MONITORING IS REQUIRED

We strongly encourage engine users who want to extend their oil life to use an oil test laboratory to ensure that the oil still meets the engine manufacturer’s specification after extended use. This will have the added advantage of giving the user a window into the secret places inside the engine and can predict a possible failure occurring before this becomes critical.

TP1

UDF filters are duel winding's of polyester and cellulose fibre sheets and act to sieve out and absorb contaminants in four different ways. They are not designed as full flow filters and are fitted as additional filters in a by-pass configuration removing 3% of the total oil flow through a restriction orifice.

This oil is filtered and returned to the engine crankcase on a continuous basis.

UDF filters remove more than 90% of all particles > 1 microns that pass straight through the standard OEM filters

Applications :- Oil Bypass Systems

HME / Transportation / Construction / Agriculture / Marine / Fixed Plant Industry

TP2

UDF filters are duel winding's of polyester and cellulose fibre sheets and act to sieve out and absorb contaminants in four different ways. They are not designed as full flow filters and are fitted as additional filters in a by-pass configuration removing 3% of the total oil flow through a restriction orifice.

This oil is filtered and returned to the engine crankcase on a continuous basis.

UDF filters remove more than 90% of all particles > 1 microns that pass straight through the standard OEM filters

Applications :- Oil Bypass Systems

HME / Transportation / Construction / Agriculture / Marine / Fixed Plant Industry

TP3

UDF filters are duel winding's of polyester and cellulose fibre sheets and act to sieve out and absorb contaminants in four different ways. They are not designed as full flow filters and are fitted as additional filters in a by-pass configuration removing 3% of the total oil flow through a restriction orifice.

This oil is filtered and returned to the engine crankcase on a continuous basis.

UDF filters remove more than 90% of all particles > 1 microns that pass straight through the standard OEM filters

Applications :- Oil Bypass Systems

HME / Transportation / Construction / Agriculture / Marine / Fixed Plant Industry